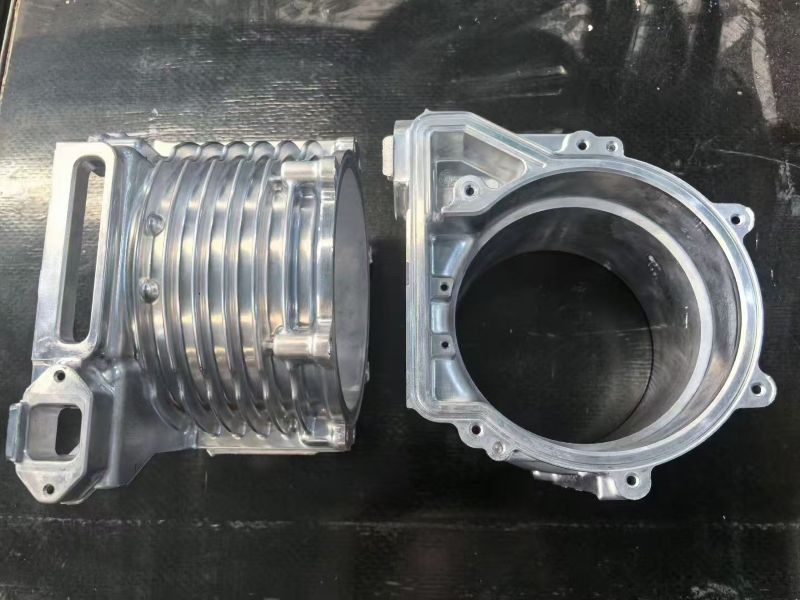

Introduction of aluminum die casting parts:

Aluminum die casting parts are precision metal products formed by injecting molten aluminum alloy into the mold cavity under high pressure and cooling and solidifying. Our aluminum die casting parts cover a number of series, including auto parts, electronic equipment housings, mechanical parts, etc., and are widely used in automotive, electronics, machinery, aerospace and other fields.

Advantages of aluminum pressure die casting component:

1. Aluminum alloy has a low density, so the aluminum pressure die casting component is light in weight, which helps to realize the lightweight design of the equipment and reduce energy consumption.

2. Aluminum alloy has good strength and rigidity, can withstand large loads, and can ensure the reliability of aluminum pressure die casting component under complex working conditions.

3. The oxide film formed on the surface of aluminum alloy has good corrosion resistance, so aluminum pressure die casting component is suitable for a variety of harsh environments.

4. Aluminum pressure die casting component can quickly conduct heat and is widely used in equipment that needs to dissipate heat, such as radiators for electronic equipment.

5. Aluminum pressure die casting parts is suitable for large-scale production, with short production cycles and can quickly meet customer order needs.

The production process of aluminum pressure die casting parts:

1. Mold design: the mold of aluminum pressure die casting parts has been precisely designed and is divided into two halves, namely the ejection mold and the cover mold. Once these halves are processed, they are used to form the shape of the desired aluminum pressure die casting parts.

2. Melting and injection: the molten aluminum is heated and injected into the mold cavity under extremely high pressure to ensure complete filling and molding.

3. Cooling and solidification: after injection, the molten aluminum is cooled and solidified in the mold.

4. Ejection and finishing: once the aluminum cools, the mold will open and the aluminum pressure die casting parts will be ejected. Further finishing techniques, such as trimming or surface treatment, can also be applied.

Application of die casting parts:

1. Automotive industry: die casting parts are usually manufactured into engine blocks, cylinder heads, wheels, transmission housings and other parts, which can effectively reduce body weight and improve fuel efficiency and vehicle performance.

2. Electronics industry: die casting parts can be produced into electronic equipment housings, radiators, internal structural parts, etc. to meet the requirements of electronic products for lightweight, heat dissipation and appearance.

3. Machinery industry: die casting parts can be manufactured into various mechanical parts, such as gears, pump bodies, brackets, etc., to improve the accuracy and reliability of mechanical products.

4. Aerospace field: die casting parts is used in the manufacture of aircraft and spacecraft parts. Through the characteristics of light weight and high strength, it helps to improve the performance and fuel efficiency of aircraft.

FAQ:

Q: What is the tolerance range of die casting parts?

A: The tolerance range of our die casting parts can be controlled from ±0.1mm to ±0.5mm. The specific tolerance depends on the complexity of die casting parts and your requirements.

Q: What treatment can be done on the surface of die casting parts?

A: The common surface treatments of die casting parts are anodizing, painting, electroplating, passivation, etc. You can choose the appropriate treatment method according to your needs for appearance and performance.

Q: What is the minimum order quantity for aluminum parts machining parts?

A: The minimum order quantity depends on the type and specifications of aluminum parts machining parts. You can communicate and negotiate with our sales team for details.

Our service:

1. Pre-sales service: we have a professional technical team to provide you with aluminum parts machining parts consulting and design suggestions to help you determine the best aluminum parts machining parts solution.

2. In-sales service: we will follow up on the progress of the order in time, maintain communication with you, and let you know the production status of the order.

3. After-sales service: we provide the quality assurance of aluminum parts machining parts, and we will respond to problems that arise during use and provide solutions in a timely manner. At the same time, we will provide you with technical support and training to help you better use aluminum parts machining parts.

Chúng tôi chịu trách nhiệm 100% về thiệt hại của toàn bộ container nếu nguyên nhân là do bao bì không đúng cách của chúng tôi. Chúng tôi có đội ngũ QC rất nghiêm ngặt để kiểm soát các vấn đề về chất lượng. Từ vật liệu đến thành phẩm, mọi bước, thanh tra viên của chúng tôi sẽ kiểm tra. Đối với mỗi đơn hàng, chúng tôi sẽ kiểm tra và ghi lại.

Có, chúng tôi có sẵn bất kỳ sản phẩm tùy chỉnh nào. Bạn có thể gửi trực tiếp bản thiết kế sản phẩm cho chúng tôi, sau đó chúng tôi sẽ thảo luận với bộ phận thiết kế chuyên nghiệp và xác nhận mọi thông tin chính xác cho bạn.

Có, chúng tôi cung cấp dịch vụ thêm logo khách hàng lên sản phẩm. Có nhiều loại dịch vụ này. Nếu bạn có nhu cầu này, vui lòng liên hệ với tôi!

Chúng tôi thường cung cấp báo giá trong vòng 48 giờ sau khi nhận được yêu cầu của bạn. Nếu bạn có yêu cầu rất khẩn cấp, vui lòng gọi điện hoặc gửi email cho chúng tôi để chúng tôi có thể ưu tiên xử lý yêu cầu của bạn.

Có, chúng tôi sẽ thử nghiệm 100% trước khi giao hàng.